Our Product Range

The wide range of products offered by Multicom consist of core materials for structural sandwiches and fiber based reinforcements of various nature. Each product category is further developed according to finishing options and technical specifications, allowing customers to choose the most suitable solution for their needs.

Reinforcements

FIBERGLASS ROVINGS

These products are made by fiberglass yarns that can be grouped in two macro categories: Direct Rovings, applied in manufacturing processes like Pultrusion, Winding, Weaving, etc.; Assembled Rovings, for applications in processes like Spray up, Chopping, SMC, etc.

CHOPPED STRANDS MAT - CMS

It’s a non-woven fabric, made by fiberglass chopped strands, randomly spread on a flat surface and binded by a chemical, that can be available in Powder or Emulsion variation. Provided by excellent mechanical properties, CSM give a significant contribution to the aesthetic outcome and a smooth surface finishing of the product.

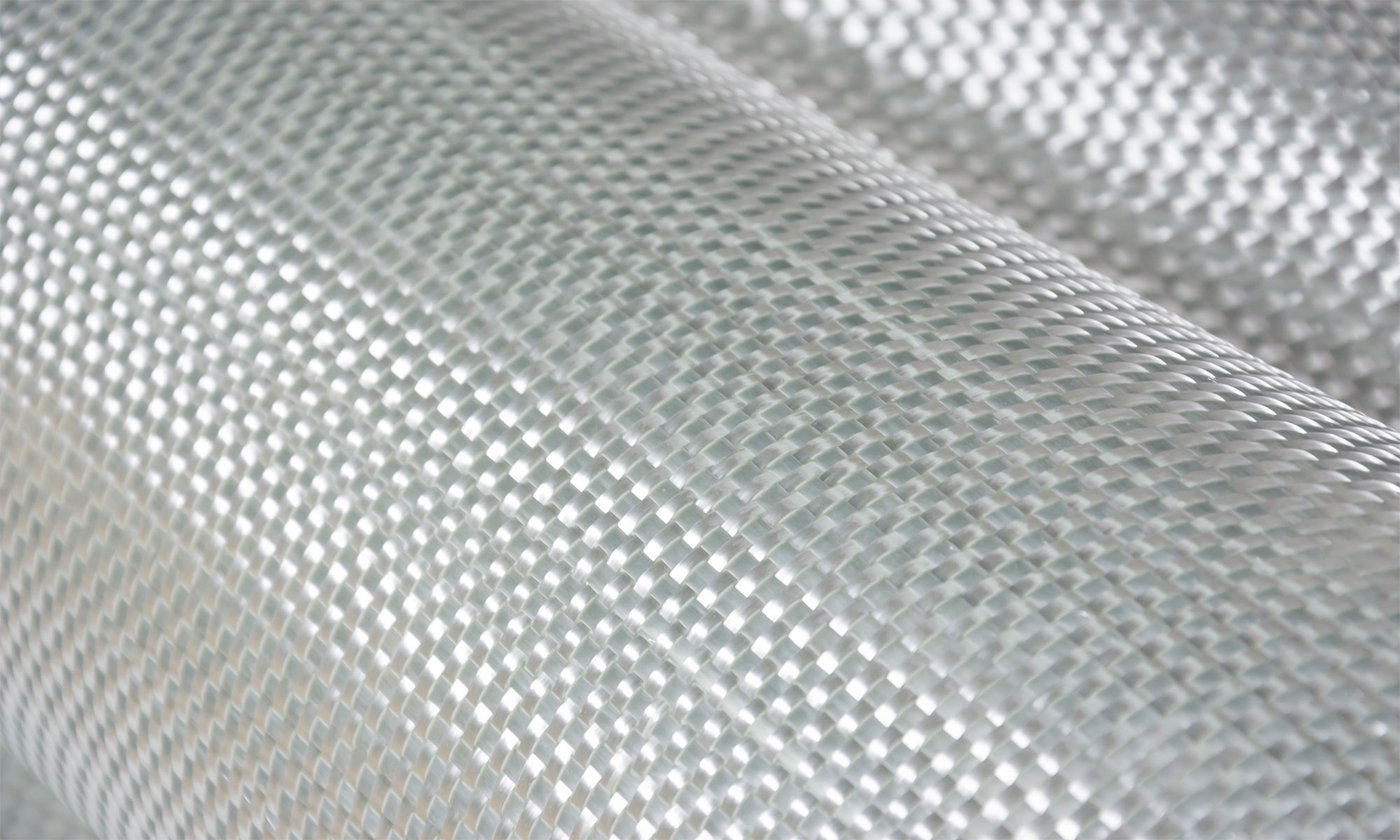

FIBERGLASS MULTIAXIAL FABRICS

These non-crimp fabrics, made by two or more fiberlgass layers, stitched by a polyester yarn, represent the evolution of Composites reinforcement fabrics. Engineered to provide high mechanical properties to the products, such as strength and lightness, can be available in several configurations that change in function of: number of fibers layers (biaxials, triaxials and quadriaxials), weight, fibers direction, combined or non with MAT.

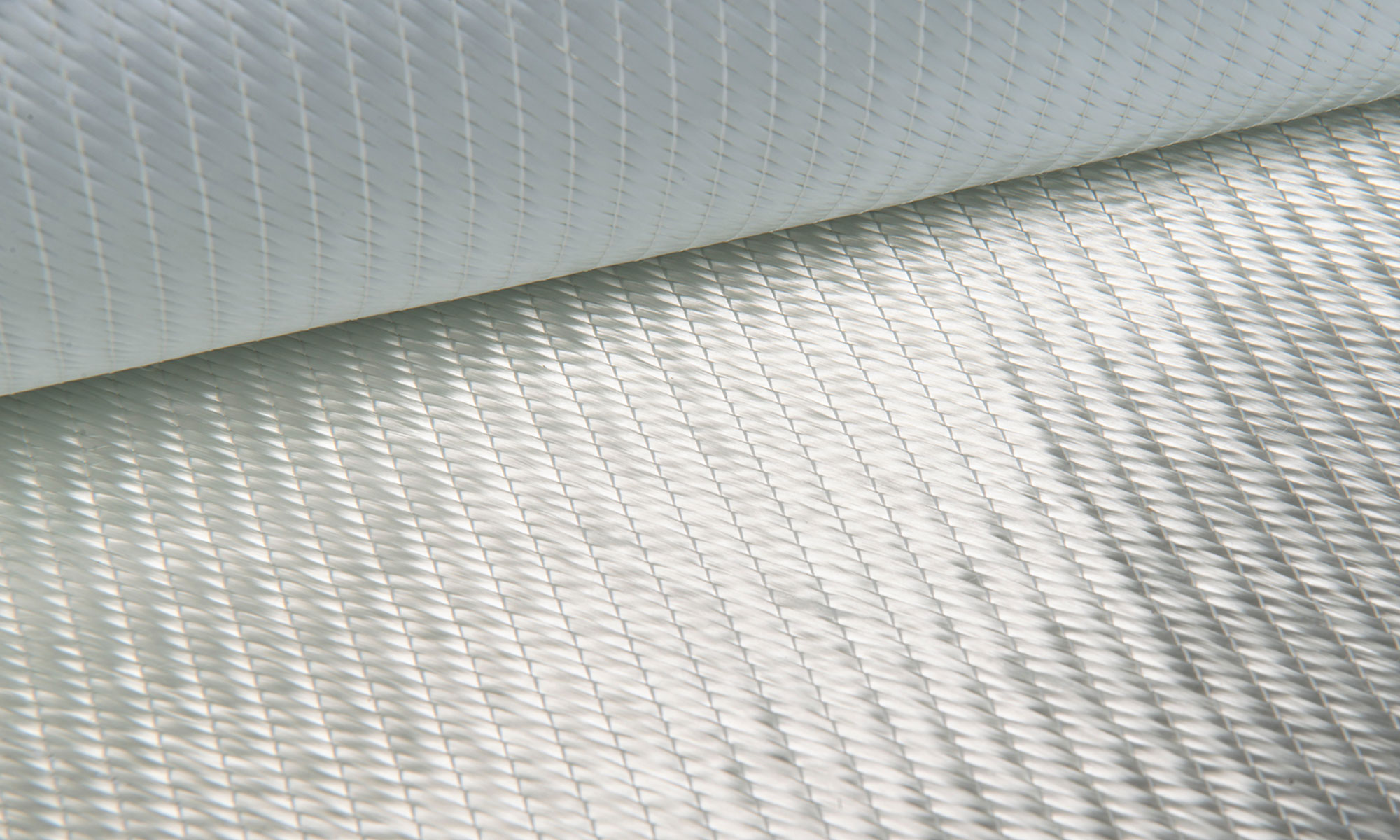

FIBERGLASS COMBO MATS

it’s a product made by a combination of a fiberglass woven roving with CSM, stitched with a polyester yarn. This kind of reinforcement is characterized by significant mechanical properties, and applied on products in which low weight is not a requirement.

Core Materials

BALSA

It represents the excellence of structural Core Materials, that has remarkable mechanical properties, like outstanding shear and compression strength, elevated Heat Deflection Temperature (above 160 °C), besides being 100% natural, sustainable and renewable.

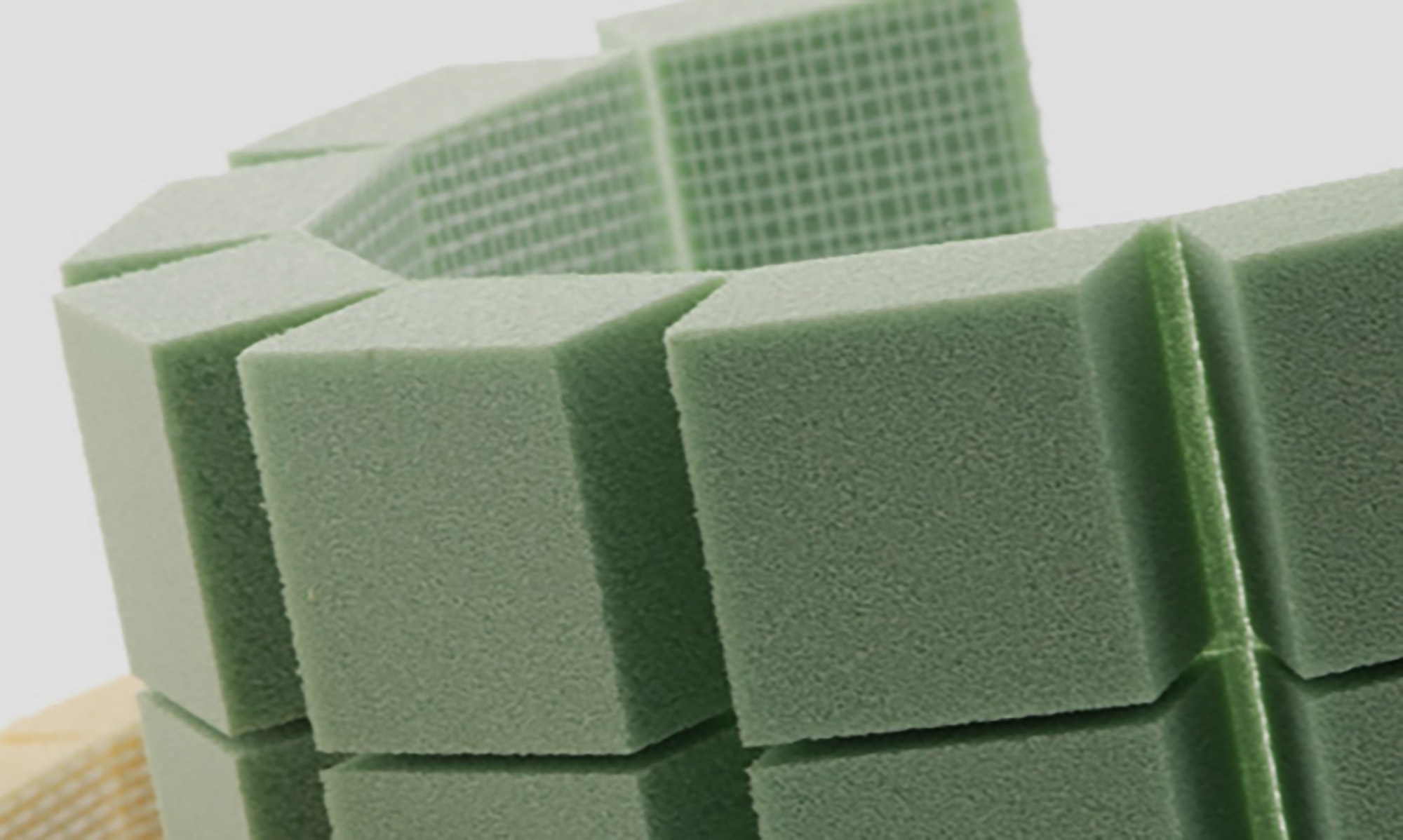

PVC FOAM

It’s a high performance material, made by a rigid PVC foam, applied in Composites structures. This core is a closed cell cross-linked polymer foam, which contains no CFC, and it’s supplied in panels.